Warp Creel is a platform that holds supply packages like cones, bobbins, or spindles in the warping process. In this article, WETEX will give a brief introduction to warp creels.

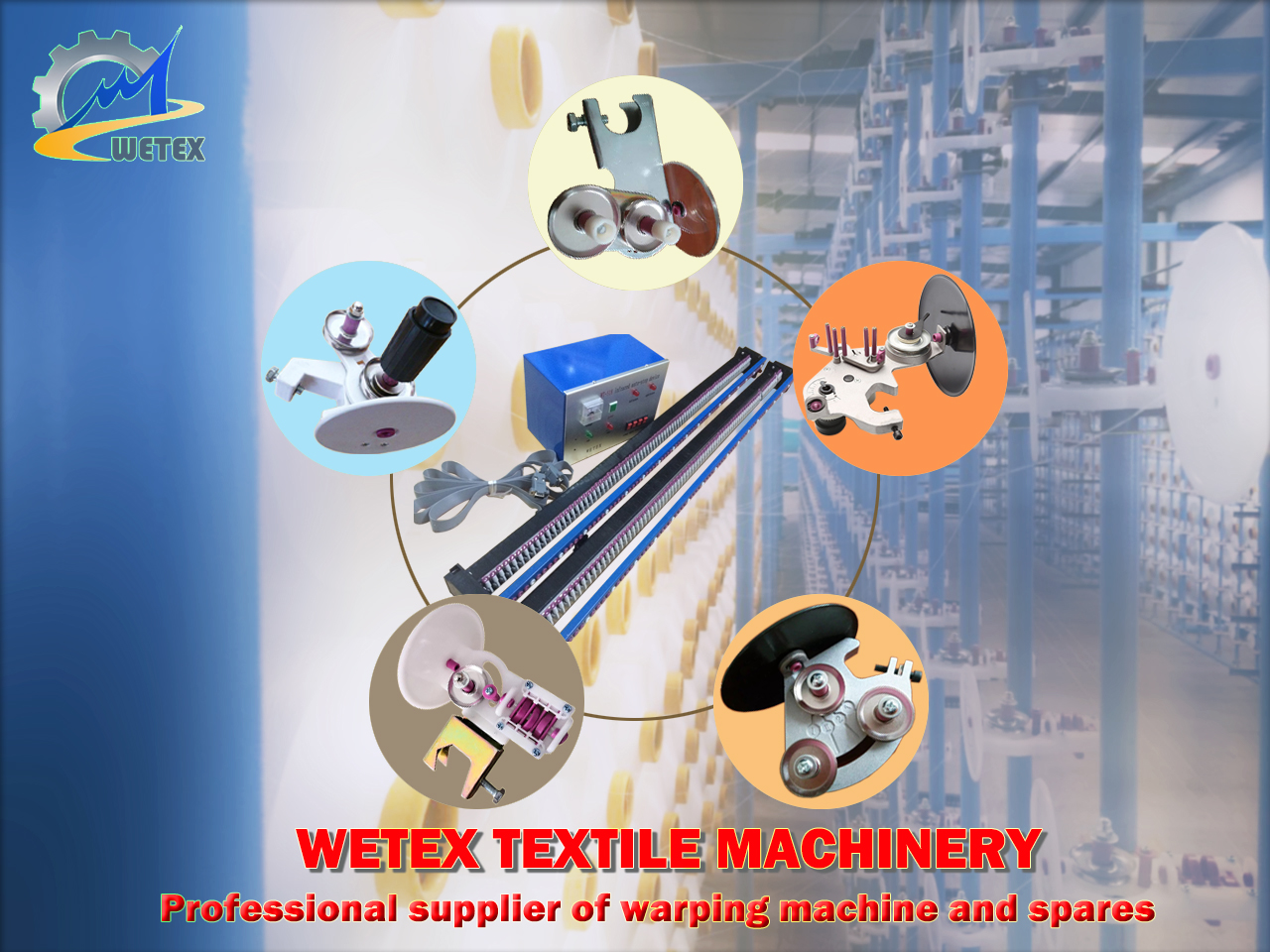

The warping machine consists of several parts such as a creel, open reed, headstock, warping drum, control system, beaming machine etc.

Feeding bobbins, cones, bobbins, or spindles are fitted on metallic frames called creels. These metallic frames consist of yarn tensioningdevices which give uniform tension. But in the latest machines instead of yarn tensioning devices they are provided with centralized tension variation having automated control technique.

Creel capacity determines the number of warping sections. Generally, the warping creel capacity is 100-2000 bobbins. But in some special field for example, glass fiber, the capacity can up to 4000~5000 bobbins. It ensures to hold the supply packages in the proper positions. Creeling includes a sampling of yarn, passing through a tensioner, yarn guide, auto-stop motion, and on to the warp headstock.

Only a single type of creel cannot give the same beaming efficiency for different types of yarns. There are many numbers of creels that are used for different purposes.

Now WETEX will state several commonly used creels.

1. V-creel

2. Rectangular creel

3. Magazine creel

4. Continuous chain creel

.

5. Automatic creel

6. Unrolling creel

7. Swivel frame creel

8. Mobile creel

9. Rotating creel

10. Single end creel

11. trolley creel

WETEX will continuously introduce the creel structure, specification and functions one by one,please follow www,wetexmc.com to learn more with us.