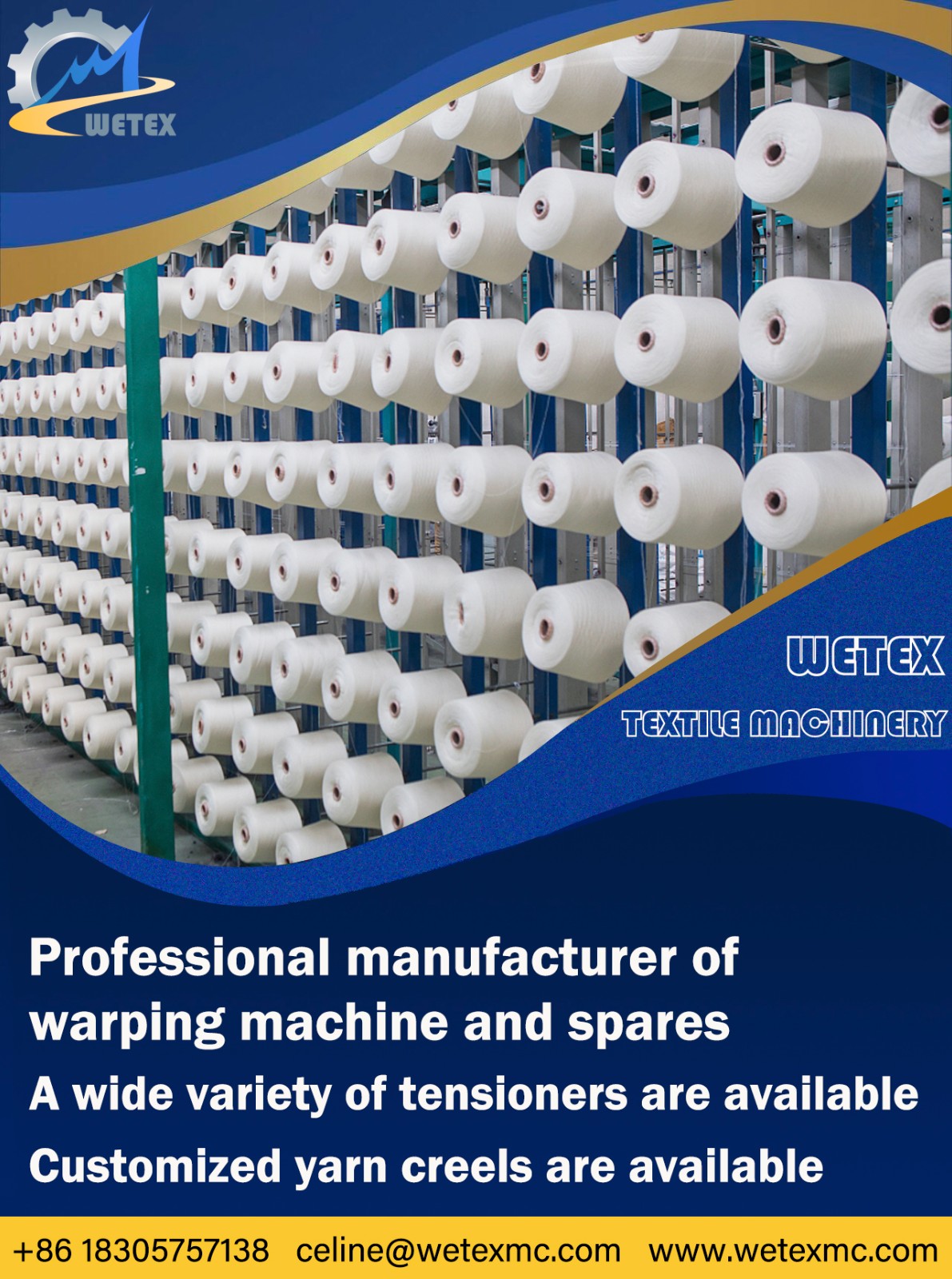

During the production process of the warping machine creel, which is an essential part of textile machinery, it mainly consists of its frame, the bobbin fixing frame, the bobbin fixing rod, and the yarn guiding device. The two ends of the bobbin fixing frame are firmly fixed on the frame, and the fixing rod is vertically attached to the bobbin fixing frame. The yarn guides are positioned in the front row of the frame. In front of each bobbin fixing frame, a tensioner fixing frame is arranged, with its two ends also fixed on the frame, and the tension device is mounted on the tensioner fixing frame. The tensioners and the fixed rods have a one-to-one correspondence.

The warping creel fixing frame and the tensioner fixing frame are placed in parallel, and the distance between them ranges from 300 to 700 mm. The tensioner is a three-column tension controller. This utility model can effectively manage and adjust the tension of each yarn, ensuring that it is evenly distributed on the warp beam head during the winding process of the warping machine. It also effectively curbs breakage and fluff issues caused by uneven tension in the warp beam process, thus safeguarding the quality of each yarn. For more information about textile machinery and warping machine creels, you can visit wetexmc.com.

Warping Machine Creel Forms and Applications in Textile Machinery

Warping Machine Creel in Diverse Forms

Based on the Yarn Introduction Method: Internal yarn introduction.

According to the Yarn Change Form: Fixed type, flip type, car type.

In Terms of the Number of Yarn Guide Columns: Two rows of yarns, four rows of yarns.

Regarding the Angle of the Creel: Rectangular, V-shaped.

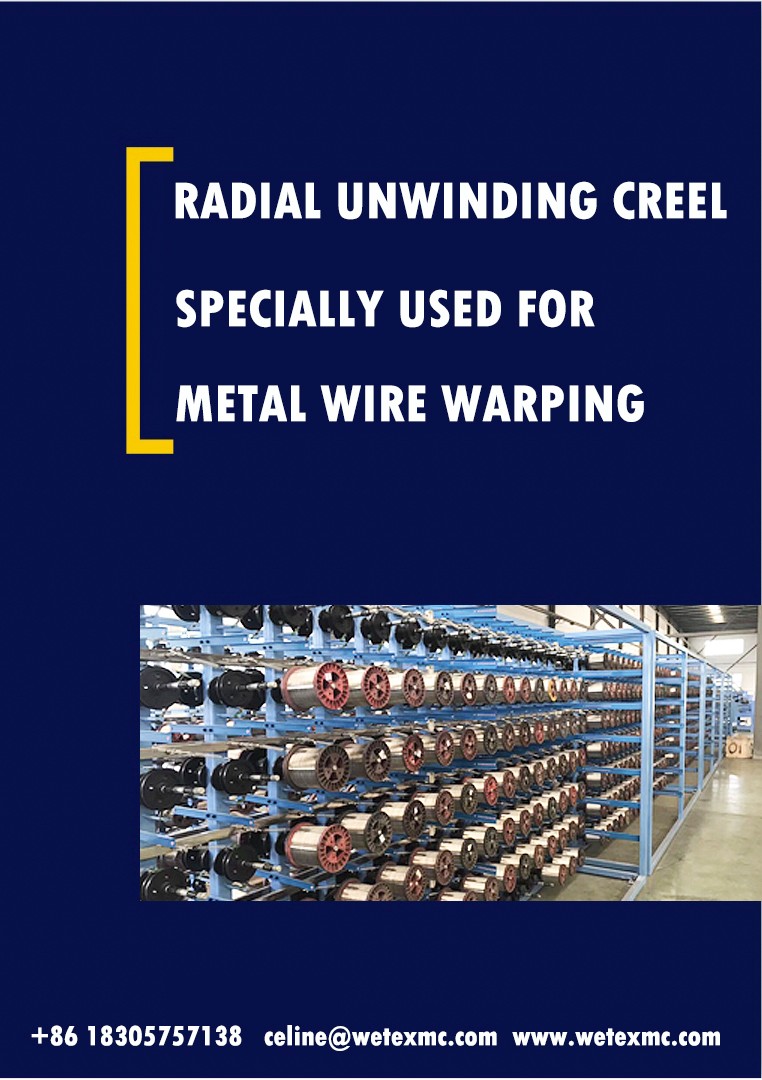

According to the Bobbin Unwinding Mode: Axial unwinding, radial unwinding.

Warping Machine Creel Configuration in Textile Machinery

The configuration of the tensioner can be customized according to the yarn material and the production process of textile machinery.

Depending on the thickness and durability of the yarn [or as per customer requirements], the tensioner and custom infrared yarn breakage detectors can be utilized. The size of the open link, the heald shaft, etc. can be increased, and a double-bone, heavy-weight heald frame can be employed to ensure stable and reliable warp opening when operating at high speed and weaving medium thick fabric in the textile machinery warping machine.